Original registered Service of EESA meters devices

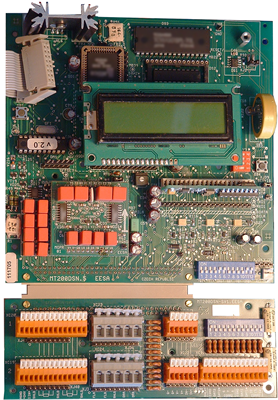

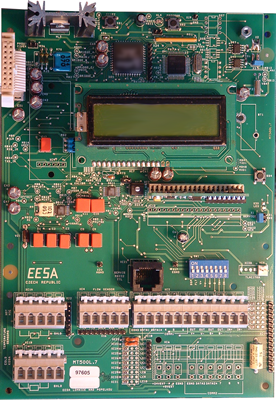

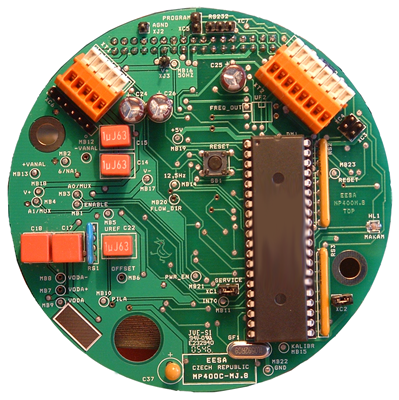

We provide all kinds of repairs, settings, calibrations, and metrological verifications for all types of EESA heat consumption and flow meters. (MT200, MT500, MT200DS, MT200DS-TUV, MP400E, MP400C, MP400CM).

These activities are carried out in our service department where we recruited dissolved EESA’s ex-employees with many years of experience and specific skills.

Since April 2014, our service activities have been taking place under accreditation of a “Registered Service”granted on basis of attestation of our technical competencies by the Czech Metrology Institute in Brno, Czech Republic.

Servicing Mechanical Parts:

- Inspections and cleaning of instruments

- Replacements of PTFE liners in flow sensors

- Replacements of sensing electrode sockets of SS316L, C-22 alloy, titanium

- Manufacture of replacement parts such as electronic casings, flow sensor housings, sensor bodies, contact flanges with round recess (female flanges), mounting studs, gaskets …

- Auxiliary material supplies (connecting or grounding wires or cables, cable bushings, other installation material), matching resistance thermometers

- Refurbishments and modifications to meter name plates

Repairs of Electronic Units:

- Overall or partial repairs of electronic units (replacements of processors, memory chips, backup batteries, and other electronic devices and parts). Fitting with communication modules 4–20mA, RS232, RS485, MBus.

- Software troubleshooting, diagnostics of instrument condition, setting to factory configuration, software reconfiguration (units of measure, conversion factors, communication protocols and rates, etc.)

You get back a completely cleaned, repaired, custom calibrated or fully metrologically verified meter.

A detailed service report showing original parameter settings and calibration chart is always enclosed with the serviced meter as well as a metrological verification certificate if required.

We can also arrange for on-site instrument uninstallation and subsequent reinstallation. You can borrow service pipe sections of the diameter required for the time of repair or calibration to bridge the gap in the pipe free of charge. The equipment concerned can thus keep its operation to minimize any possible losses from downtime.

Metrological traceability is provided on a contractual basis with an authorized metrological laboratory.

If you are in need of repair, refurbishment, calibration or verification, please send your meter using any delivery service to the address of our facility.